Leading battery plant sets monthly output record

2025-05-13 19:05:59

By Chen Zai.

The Yichang plant of a leading local battery maker achieved record monthly output in April, with even greater production expected in May. CORNEX New Energy Innovation Technology Co., Ltd. delivered 1.8 GWh of batteries last month, which is equivalent to the battery capacity of 24,000 EVs. Output is expected to reach 2.5 GWh this month.

CORNEX specializes in the research and development, manufacturing, sales, and servicing of energy storage batteries, EV batteries, and energy management systems. Its Yichang plant represents an investment of around 60 billion yuan (US$8.45 billion) and has an annual production capacity of 150 GWh. The facility operates 26 automated positive electrode coating machines, applying lithium iron phosphate at 65 meters per minute.

The Yichang plant of a leading local battery maker achieved record monthly output in April, with even greater production expected in May. CORNEX New Energy Innovation Technology Co., Ltd. delivered 1.8 GWh of batteries last month, which is equivalent to the battery capacity of 24,000 EVs. Output is expected to reach 2.5 GWh this month.

CORNEX specializes in the research and development, manufacturing, sales, and servicing of energy storage batteries, EV batteries, and energy management systems. Its Yichang plant represents an investment of around 60 billion yuan (US$8.45 billion) and has an annual production capacity of 150 GWh. The facility operates 26 automated positive electrode coating machines, applying lithium iron phosphate at 65 meters per minute.

After recent upgrades at CORNEX’s Yichang plant, positive electrode coating machines now coat aluminum foil at 65 meters per minute up from 50 meters per minute.

Vice General Manager Jiao Linsen said the Yichang base will fulfill its first EU orders in May, further expanding CORNEX’s presence in international markets.

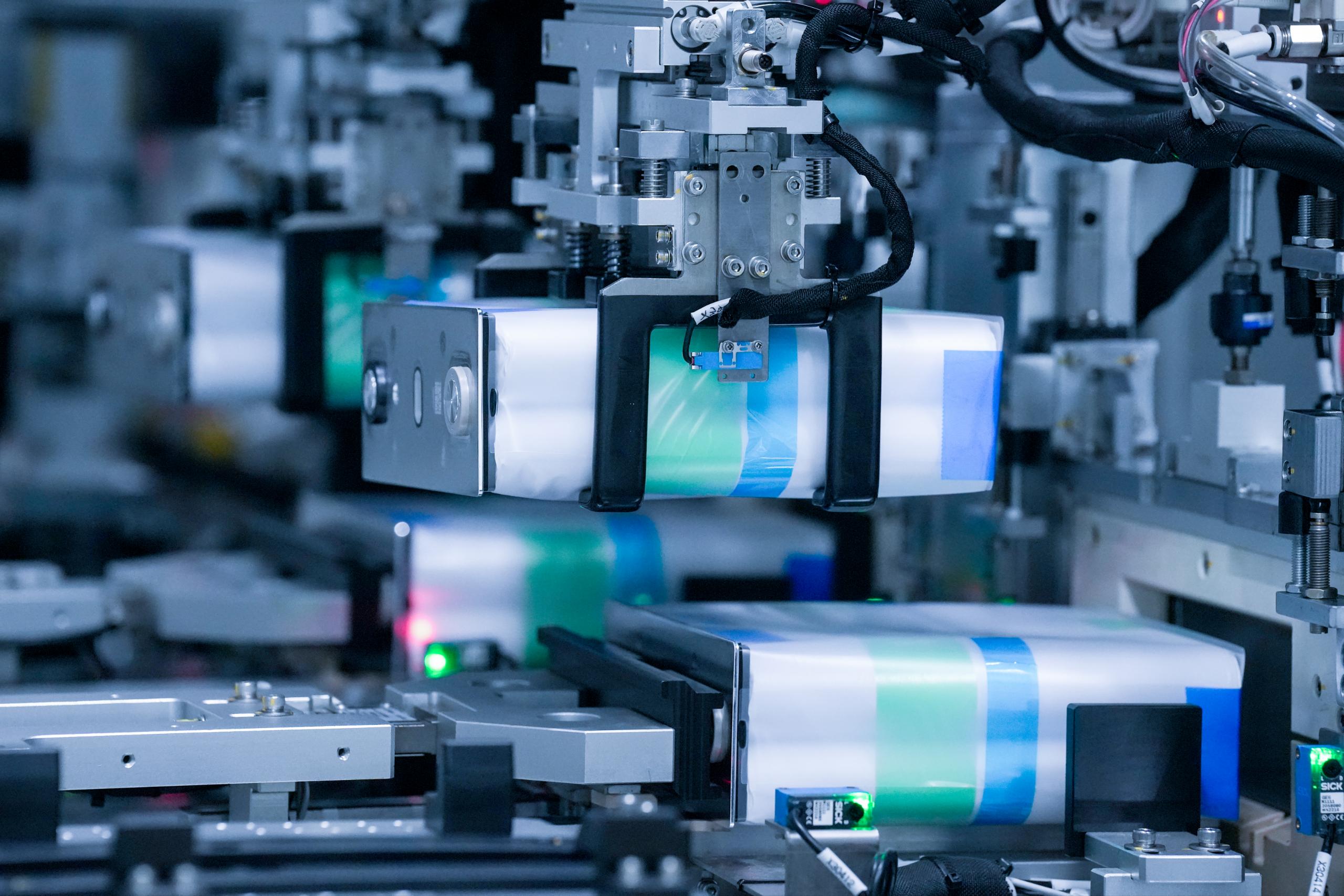

Battery cells produced at CORNEX's Yichang plant.

Booming production and sales are credited to process upgrades, technological innovation, and growing market recognition. Following a recent upgrade, each positive electrode coating machine has increased its output from 5-6 to 6-8 batteries per minute, and coating speed from 50 to 65 meters per minute. Additionally, new R&D breakthroughs have been applied in production, such as reducing the anode copper foil thickness from 7 to 4.5 micrometers, thereby improving battery energy density.

CORNEX New Energy Innovation Technology Yichang plant

With strong product performance and reliable delivery, CORNEX’s overseas orders surpassed 30 GWh last year, earning recognition from over 200 clients in the European Union, the Middle East, and North America.

Currently, the Yichang plant is testing its No.4 Workshop, which is scheduled to begin operations later this month. It will expand the facility’s capacity by adding the lamination process.

*The lamination process in lithium-ion battery manufacturing involves bonding electrodes and separators together to create intermediate cell units.

Reporter Long Jie and Xu Mingming, Correspondent Jin Xiaoyan contributed to this story.