Digital twin technology powers green shipbuilding

2025-10-20 19:10:44

By Yan Wanqin.

An Yichang shipbuilder is leading the industry's green transformation by merging digital innovation with eco-friendly processes.

At Hubei Zhongnan Pengli Marine Sounding System Engineering Co., Ltd., ship design engineer Yang Chengyong creates detailed 3D models in which every steel plate, pipeline, and cable is precisely replicated. This digital twin approach is making things more efficient and paving the way for greener ship manufacturing.

Founded in 2009 as a leader in marine sounding instruments, the company has since expanded into smart and eco-friendly ships, delivering electric patrol boats for the Huangbai River basin and electric tour boats for Xiandao Lake.

By building a complete digital replica before construction, the company achieves a material utilization rate of up to 90 percent. "We test and solve problems digitally before the physical construction begins," Yang explained. This innovative approach helps detect and resolve issues early, reducing waste and saving time.

This technology, which was previously used only by major shipyards, has given Zhongnan Pengli a major boost. All its ships are now designed using 3D modeling, cutting the material error rate to below 2 percent and improving construction efficiency by about 50 percent. This reduces costs and ensures consistent quality and reliable estimates for construction scheduling.

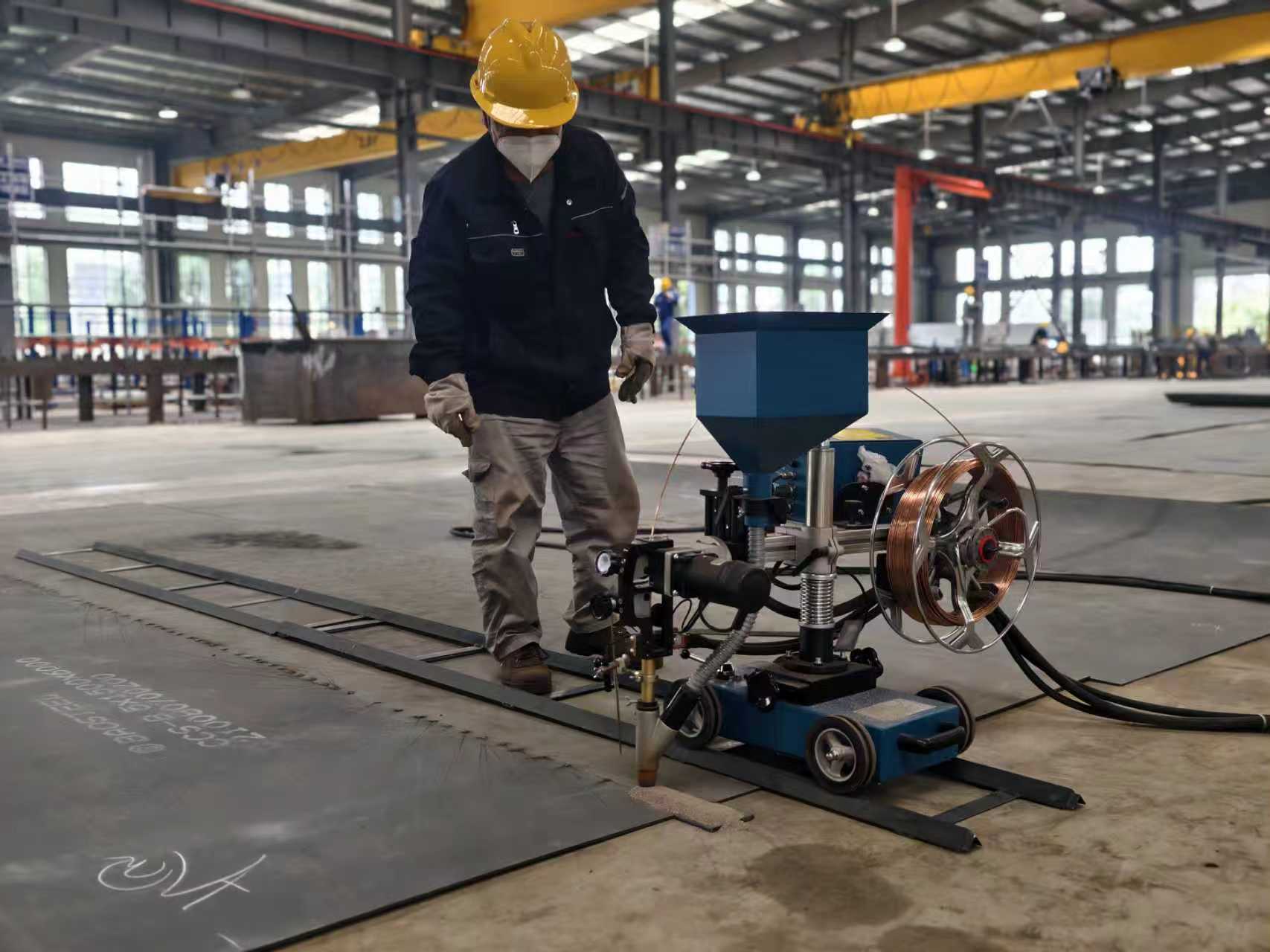

In the indoor production workshop, a submerged arc welding machine operates smoothly along a preset track, joining thin steel plates without visible smoke or intense light. This is a stark contrast to traditional open-air shipyards.

An Yichang shipbuilder is leading the industry's green transformation by merging digital innovation with eco-friendly processes.

At Hubei Zhongnan Pengli Marine Sounding System Engineering Co., Ltd., ship design engineer Yang Chengyong creates detailed 3D models in which every steel plate, pipeline, and cable is precisely replicated. This digital twin approach is making things more efficient and paving the way for greener ship manufacturing.

Founded in 2009 as a leader in marine sounding instruments, the company has since expanded into smart and eco-friendly ships, delivering electric patrol boats for the Huangbai River basin and electric tour boats for Xiandao Lake.

By building a complete digital replica before construction, the company achieves a material utilization rate of up to 90 percent. "We test and solve problems digitally before the physical construction begins," Yang explained. This innovative approach helps detect and resolve issues early, reducing waste and saving time.

This technology, which was previously used only by major shipyards, has given Zhongnan Pengli a major boost. All its ships are now designed using 3D modeling, cutting the material error rate to below 2 percent and improving construction efficiency by about 50 percent. This reduces costs and ensures consistent quality and reliable estimates for construction scheduling.

In the indoor production workshop, a submerged arc welding machine operates smoothly along a preset track, joining thin steel plates without visible smoke or intense light. This is a stark contrast to traditional open-air shipyards.

A submerged arc welding machine operates at the indoor production workshop of Zhongnan Pengli.

A submerged arc welding machine operates at the indoor production workshop of Zhongnan Pengli."Open-air operations are easily affected by the external environment. A strong wind can spread dust far and wide, making pollution hard to control," said Yu Ze, the company's construction director. By using this new technology, the company can move the manufacturing process indoors and reduce the amount of harmful fumes, dust, and noise.

The indoor workshop also has advanced equipment that extracts dust and pollution, which further reduces the impact on the environment and provides workers with a safer, healthier, and more comfortable workplace.

Zhongnan Pengli’s indoor shipbuilding workshop.

To overcome common challenges in welding thin steel or aluminum plates, such as deformation and poor surface finish, Zhongnan Pengli has developed a specialized automated process that combines precise heat control with advanced welding technology. Skilled technicians can now produce higher quality components and better-looking hulls with lower energy consumption.

Yang Chunyan and Wang Fei contributed to this story.